Content

- 1 Understanding the Difference Between Auto Accessories and Auto Body Parts

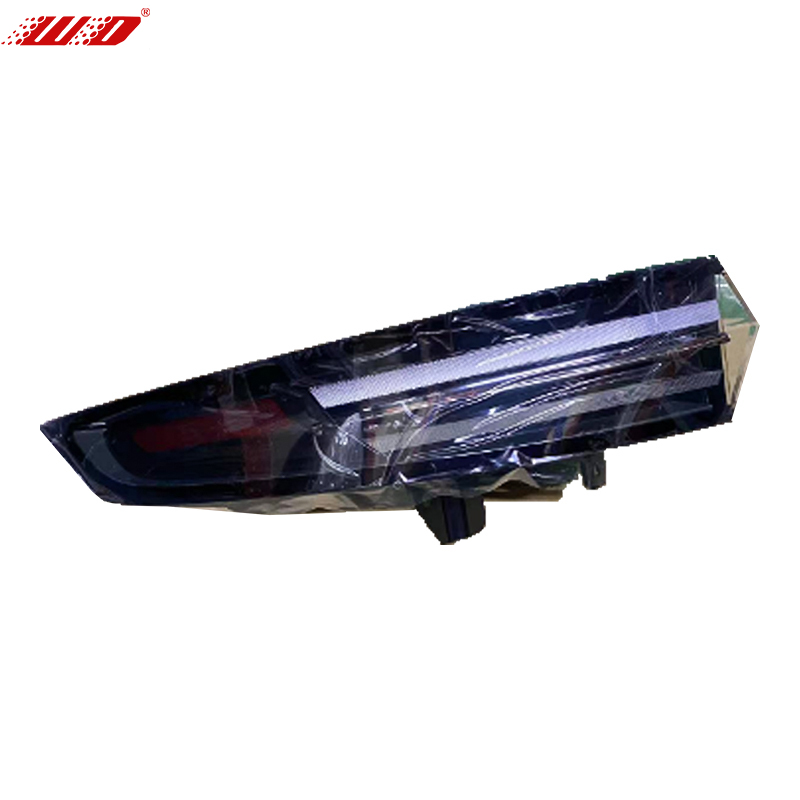

- 2 Common Auto Body Parts and Their Functional Roles

- 3 Material Selection and Manufacturing Standards

- 4 Fitment Accuracy and Installation Considerations

- 5 Quality Control and Durability Testing

- 6 Selecting the Right Supplier for Auto Accessories and Body Parts

Understanding the Difference Between Auto Accessories and Auto Body Parts

An auto accessory typically enhances vehicle functionality, appearance, or comfort without altering structural integrity. Examples include floor mats, roof racks, seat covers, lighting upgrades, and infotainment components. In contrast, an auto body part forms part of the vehicle’s structural or exterior shell, such as bumpers, fenders, hoods, doors, and grilles. These components directly influence safety performance, aerodynamics, and impact resistance.

Understanding this distinction is critical when sourcing products for repair, customization, or resale. Accessories are often bolt-on additions, while body parts must meet stricter dimensional tolerances and safety standards.

Common Auto Body Parts and Their Functional Roles

Auto body parts protect internal systems and maintain the vehicle’s structural rigidity. Material selection and manufacturing precision determine crash performance and long-term durability.

- Bumpers designed to absorb impact energy and reduce collision damage

- Fenders protecting wheel wells from debris and water intrusion

- Hoods shielding engine components while supporting airflow design

- Doors and quarter panels contributing to side-impact strength

Modern body panels are often manufactured from high-strength steel, aluminum alloys, or reinforced composites to balance weight reduction and structural safety.

Material Selection and Manufacturing Standards

Steel and Aluminum Body Panels

High-strength steel provides cost-effective durability and impact resistance. Aluminum reduces vehicle weight, improving fuel efficiency and handling. Proper corrosion protection treatments such as galvanization or electrocoating extend service life.

Plastic and Composite Accessories

Many auto accessories are manufactured from ABS plastic or polypropylene due to their flexibility and weather resistance. UV-stabilized materials prevent fading and cracking when exposed to sunlight. Injection molding ensures consistent shape and fitment.

Fitment Accuracy and Installation Considerations

Auto body parts must match original equipment manufacturer specifications to ensure proper alignment. Incorrect panel gaps can affect aerodynamics, noise insulation, and overall appearance. Pre-drilled mounting points and precision stamping reduce installation time and improve assembly accuracy.

Auto accessories often offer universal or vehicle-specific fitment options. Vehicle-specific products provide cleaner integration, while universal designs allow broader compatibility.

| Component Type | Primary Purpose | Material Example |

| Bumper | Impact protection | Steel with plastic cover |

| Roof Rack | Cargo support | Aluminum alloy |

| Side Mirror Cover | Exterior protection and styling | ABS plastic |

| Fender | Wheel arch protection | High-strength steel |

Quality Control and Durability Testing

Reputable manufacturers test auto body parts for dimensional accuracy, coating adhesion, and corrosion resistance. Salt spray testing evaluates resistance to rust, while impact testing ensures compliance with safety standards. Accessories undergo vibration and weather exposure testing to confirm long-term performance under varying environmental conditions.

Certification and compliance documentation are important for commercial buyers and distributors seeking reliable supply chains.

Selecting the Right Supplier for Auto Accessories and Body Parts

When sourcing auto accessories and auto body parts, consider manufacturing capability, material traceability, and quality inspection procedures. Suppliers with advanced stamping lines, robotic welding systems, and precision molds typically deliver consistent products with reduced defect rates.

- Verify compatibility with specific vehicle models and production years

- Confirm corrosion protection standards and coating processes

- Evaluate packaging methods to prevent transport damage

- Request technical drawings or fitment data before bulk purchase

Careful evaluation ensures that both accessories and structural components meet performance expectations, support vehicle safety, and maintain aesthetic consistency throughout the product lifecycle.

English

English русский

русский Español

Español