Content

- 1 Understanding How Parts Selection Affects Li Auto Vehicle Longevity

- 2 Matching Parts to Vehicle Systems and Driving Conditions

- 3 Choosing Between OEM and Aftermarket Li Auto Parts

- 4 Focusing on High-Wear Li Auto Components

- 5 Ensuring Correct Fitment and Installation Compatibility

- 6 Building a Long-Term Maintenance Strategy Around Parts Selection

Understanding How Parts Selection Affects Li Auto Vehicle Longevity

The service life of a Li Auto vehicle is closely linked to the quality, compatibility, and application accuracy of its replacement parts. Unlike general maintenance advice, proper parts selection directly influences system stability, wear control, and long-term operating efficiency. From powertrain components to electronic control modules, each part interacts with others under specific design parameters. Selecting parts that align with these parameters helps maintain original performance characteristics and reduces cumulative mechanical stress.

Matching Parts to Vehicle Systems and Driving Conditions

Li Auto vehicles integrate hybrid systems, electronic control units, and complex chassis structures. Replacement parts should therefore be selected based on system-level compatibility rather than single-component availability. Driving conditions such as frequent short trips, high-load urban traffic, or extended highway use also affect component wear patterns and should be considered during part selection.

Key System Areas Requiring Accurate Part Matching

- Powertrain and hybrid system components that must align with control logic and torque output requirements

- Cooling and thermal management parts that support stable operating temperatures under varying loads

- Suspension and steering components that influence long-term chassis alignment and ride stability

Choosing Between OEM and Aftermarket Li Auto Parts

When extending vehicle lifespan is the priority, understanding the differences between OEM and aftermarket parts becomes essential. OEM parts are designed according to original engineering standards and typically offer predictable fitment and performance. Aftermarket parts vary in quality and application focus, making careful evaluation necessary.

| Part Type | Fitment Accuracy | Lifecycle Consistency |

| OEM Parts | Designed to original specifications | Stable performance over long-term use |

| Aftermarket Parts | Depends on manufacturer and application | Varies by material and design focus |

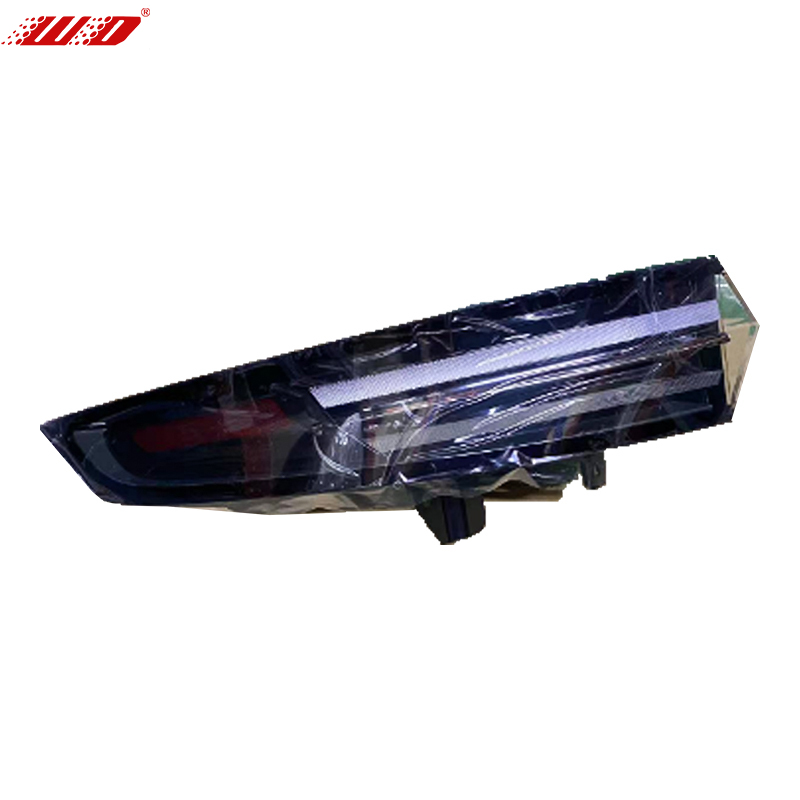

Focusing on High-Wear Li Auto Components

Certain components experience accelerated wear due to friction, heat, or repeated load cycles. Selecting durable replacements for these parts has a direct impact on overall vehicle lifespan. Using materials and designs suited to the vehicle’s operating environment helps reduce secondary wear on connected systems.

Common High-Wear Areas to Monitor

- Brake system components subject to repeated thermal stress

- Suspension bushings and joints affected by road conditions and vehicle weight

- Filters and seals exposed to contaminants and temperature variation

Ensuring Correct Fitment and Installation Compatibility

Even high-quality parts can shorten vehicle lifespan if fitment is inaccurate. Li Auto models may differ by production year, configuration, or system revision, making verification essential. Proper fitment minimizes abnormal vibration, uneven load distribution, and premature wear across related components.

Building a Long-Term Maintenance Strategy Around Parts Selection

Extending the lifespan of a Li Auto vehicle is most effective when parts selection is integrated into a long-term maintenance plan. Tracking replacement intervals, observing wear patterns, and maintaining consistency in part quality help preserve system balance. Over time, this approach reduces unexpected failures and supports stable vehicle performance throughout extended service life.

English

English русский

русский Español

Español