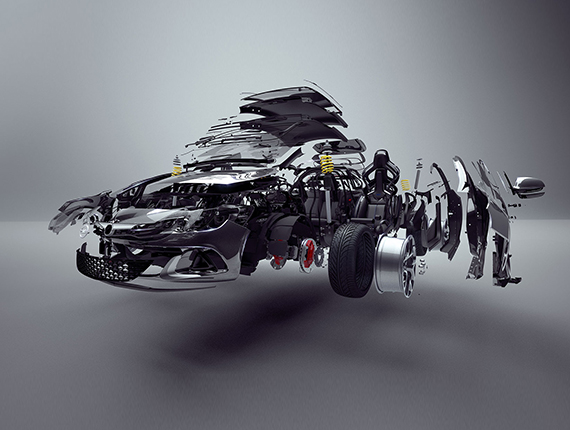

As a large comprehensive auto parts supplier, We provide one-stop solutions for OEM parts of well-known auto brands such as Ideal, Leapmotor, Polaris, Lantu, Wenjie, Xiaomi, Chery, BYD, Geely, Changan, and high-quality brand parts. Our company has established strategic partnerships with many OEMs and is the agent distributor of their original aftermarket parts.

Customize Service

-

Requirement Confirm

Clearly define customization goals, determine accessory types, vehicle models, years, original accessory data, and other information. -

Design and Development

3D modeling, using CAD software (such as SolidWorks, Alias) for structural design, 3D printing or CNC machining for rapid prototyping, used for physical verification. -

Sample Confirmation

Before production are used to inform them of the physical, quality, functionality, or performance of the product. These samples are sometimes customized according to customer requirements to confirm quality. -

Production and Quality Control

Large scale production, and then quality inspection, durability testing (such as UV weather resistance, impact resistance), surface treatment (painting, electroplating, anodizing, etc.), and process inspection. -

Delivery and Installation

Logistics packaging, vulnerable parts (such as carbon fiber components) need to be customized with shockproof packaging, and installation instructions or video tutorials should be provided. -

After-sales Service

Clearly define the warranty scope and provide cleaning and maintenance recommendations for special materials such as matte paint.

High-technology R&D Capacity

After years of development, we have become a globally renowned provider of OEM brand auto parts solutions.

Large Capacity and Adequate SKU Stock

More than 50,000 square meters of modern warehousing, and the inventory SKU is maintained at more than 100,000 all year round. Over 80,000 square meter intelligent production base and 26 injection molding equipment production lines make an annual production capacity of more than 2 million pieces.

-

● 50000㎡ modern warehouse

● 80000㎡ production base

● 26 sets production lines

● 100000 SKU stock

● 2000000 annual production capacity

High standard, High performance Auto Parts

Our company adhering to the enterprise spirit of "let more cars use good accessories", to bring better service experience to the majority of car users.

Our factory has passed the SGS management certification. With advanced production technology and strict quality control system, it continues to provide customers with high-standard, high-performance high-quality auto parts, and advocates green innovation, and continuously increases the use of green energy in corporate operations.

TECHNICAL SUPPORT

Tremendous strength to provide customers with a complete service system.

-

One-stop OEM Auto Parts Solution Provider Over 17 Years

--Technical Consulting

--Product Selection

--Equipment Installation

--Commissioning

--Technical Training

--After-Sales Maintenance

English

English русский

русский Español

Español