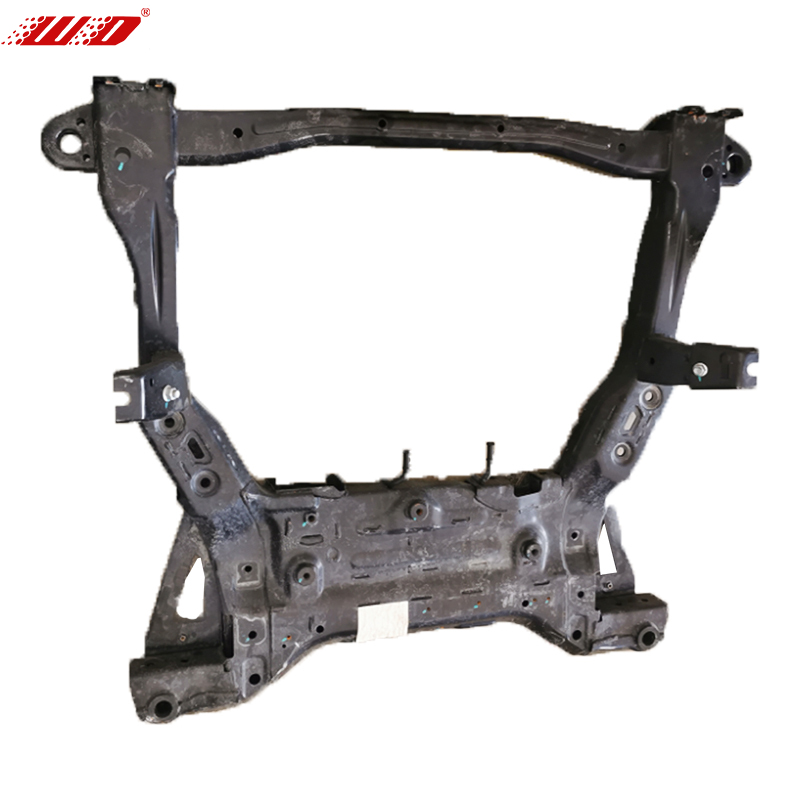

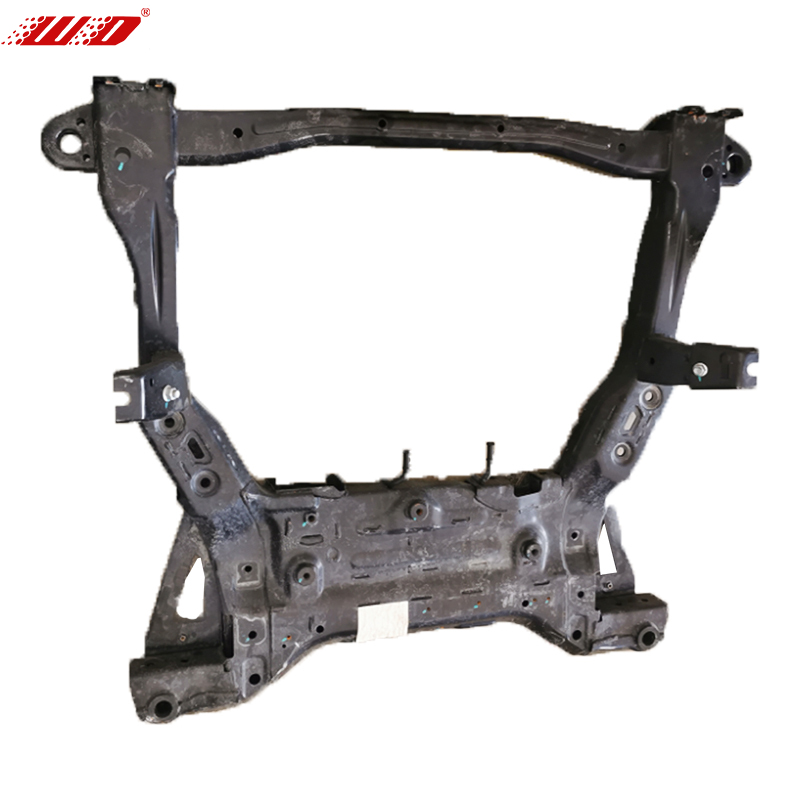

The Auto L6 front axle is a fundamental component in a wide range of commercial vehicles, trucks, and heavy-duty automobiles. Acting as both a structural and functional part of the vehicle, the front axle is responsible for load-bearing, steering stability, suspension support, and overall vehicle safety. Understanding the design, functions, and applications of the Auto L6 front axle provides insight into its critical role in vehicle performance and durability.

Content

Overview of the Auto L6 Front Axle

An Auto L6 front axle is engineered to handle moderate to heavy loads while ensuring precise steering and stability. The “L6” designation typically refers to its load rating, structural design, or model classification within a manufacturer’s product lineup. Unlike basic front axles, the Auto L6 is designed with enhanced structural integrity, making it capable of withstanding bending, torsional stress, and dynamic forces encountered during commercial and industrial vehicle operation.

The front axle connects the vehicle frame to the front wheels and integrates with suspension and steering systems. Its robust design allows vehicles to transport cargo safely while providing consistent handling performance on various road conditions, including uneven terrain, heavy traffic, or industrial sites.

Key Functions of an Auto L6 Front Axle

1. Load Bearing

The primary function of the front axle is to support the vehicle’s weight, including the engine, front suspension components, and part of the cargo. The Auto L6 front axle distributes this weight evenly across the front wheels, maintaining vehicle balance and preventing excessive stress on either side. Proper load distribution also contributes to tire longevity and overall road stability.

2. Steering Support

The front axle serves as the mounting point for steering components such as tie rods, steering knuckles, and control arms. By providing a stable platform for these elements, the Auto L6 front axle ensures precise wheel alignment and steering responsiveness. This is particularly important for vehicles that operate in urban environments or industrial settings where accurate maneuverability is required.

3. Shock Absorption and Suspension Integration

Working closely with the vehicle’s suspension system, the Auto L6 front axle absorbs shocks and vibrations from uneven surfaces. This function reduces stress on the chassis and other mechanical components while enhancing driver comfort. Vehicles with well-designed front axles experience less structural fatigue over time, increasing the lifespan of both the axle and surrounding systems.

4. Structural Durability and Strength

The Auto L6 front axle is designed to resist bending, torsion, and impact forces, which can occur when vehicles traverse rough terrain or carry heavy loads. High-strength materials and precision manufacturing processes ensure the axle maintains its structural integrity under demanding operating conditions. This durability is critical for maintaining safety and performance in commercial and industrial vehicles.

5. Wheel Alignment and Vehicle Stability

Maintaining proper wheel geometry is essential for vehicle control. The Auto L6 front axle ensures correct alignment of the front wheels, optimizing tire-road contact and enhancing stability. This alignment improves braking efficiency, reduces tire wear, and supports safe cornering, particularly under load.

Common Applications of Auto L6 Front Axles

The Auto L6 front axle is widely used in multiple vehicle types due to its load capacity and reliability:

- Light and Medium-Duty Trucks: Ensures stable steering and load distribution for daily transport operations.

- Commercial Delivery Vehicles: Supports heavy cargo and frequent stop-and-go driving in urban environments.

- Municipal and Utility Vehicles: Provides durability for waste collection trucks, street sweepers, and service vehicles.

- Industrial and Construction Vehicles: Offers strength and stability for vehicles operating on rough terrain, including site transport trucks and equipment carriers.

Maintenance and Care

Proper maintenance of the Auto L6 front axle is essential for safety, performance, and longevity:

- Lubrication: Regular lubrication of bearings, joints, and moving parts reduces friction and prevents premature wear.

- Alignment Checks: Ensures tires wear evenly and steering remains precise. Misalignment can lead to handling issues and increased maintenance costs.

- Visual Inspections: Checking for cracks, corrosion, or other damage allows for early intervention and avoids catastrophic failure.

- Component Replacement: Timely replacement of worn bushings, seals, or bearings maintains structural integrity and smooth operation.

Advantages of Using an Auto L6 Front Axle

- Enhanced Load Capacity: Designed to handle moderate to heavy loads without compromising safety or performance.

- Improved Steering Precision: Provides stable mounting for steering components, ensuring better maneuverability.

- Durability: Built to withstand torsion, bending, and impact forces for long service life.

- Ease of Maintenance: Simple inspection and component replacement reduce downtime and maintenance costs.

Conclusion

The Auto L6 front axle is a vital component in commercial, industrial, and municipal vehicles, combining load-bearing strength, steering precision, and durability. Its robust design ensures vehicle stability, efficient handling, and safe operation, while proper maintenance enhances longevity and reliability. By integrating with suspension and steering systems, the Auto L6 front axle plays a central role in delivering performance, safety, and efficiency in a wide range of automotive applications.

English

English русский

русский Español

Español